Paper Cup Machine

The NS-G2200 Paper Cup Machine is an advanced and effective option for producing disposable paper cups. One of its best features is the gear system, which allows it to run faster than regular machines, this allows it to run at speeds of up to 100 cups per minute. Also, this machine is made for larger 22oz cups, making it perfect for businesses that need to produce big and strong cups quickly.

NS-G2200

.webp&w=3840&q=75)

Speed

100 Pcs/Min.

Paper Specification

170-380 Gsm

Size Range

16Oz/480Ml-24oz/720Ml

This model is equipped with latest technology that performs auto paper feeding and has paper anti-reverse device, ultrasonic welding heaters, automatic lubrication system, robotic arm, paper tube that helps in punching and folding bottom, pre-heating, knurling, curling,and collecting cups/bowls. Machine can make various size of cups/bowls by changing moulds. This model has been designed specifically to manufacture cold drink cups in customised sizes.

Speed

100 Pcs/Min.

Paper Specification

170-380 Gsm

Size Range

16Oz/480Ml-24oz/720Ml

Process of Cup Formation

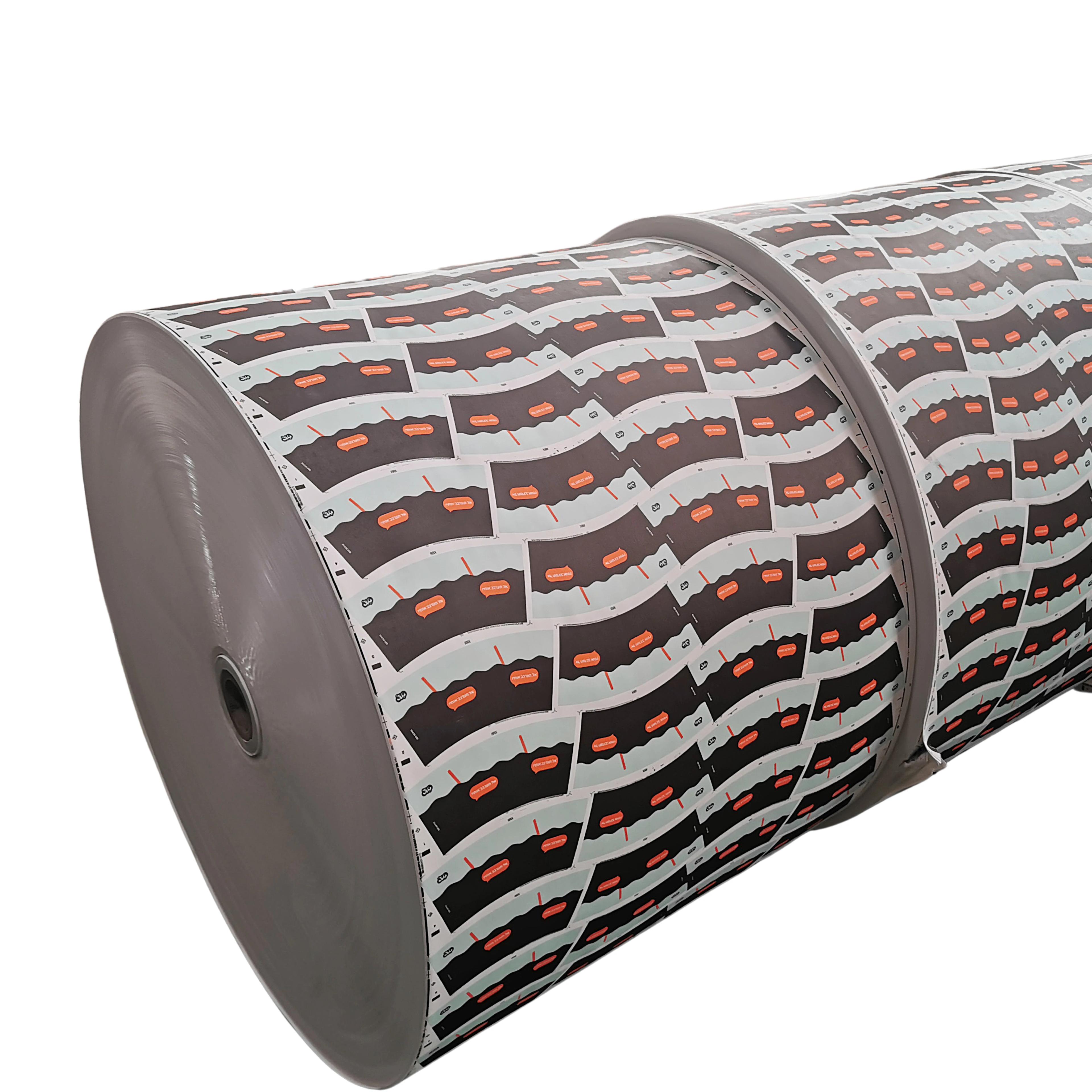

1. Paper Roll

The process begins with the sourcing of large paper rolls, typically made from food-grade paper that has been coated with a thin layer of polyethylene to make it waterproof. These rolls are the raw material that will be transformed into paper cups.

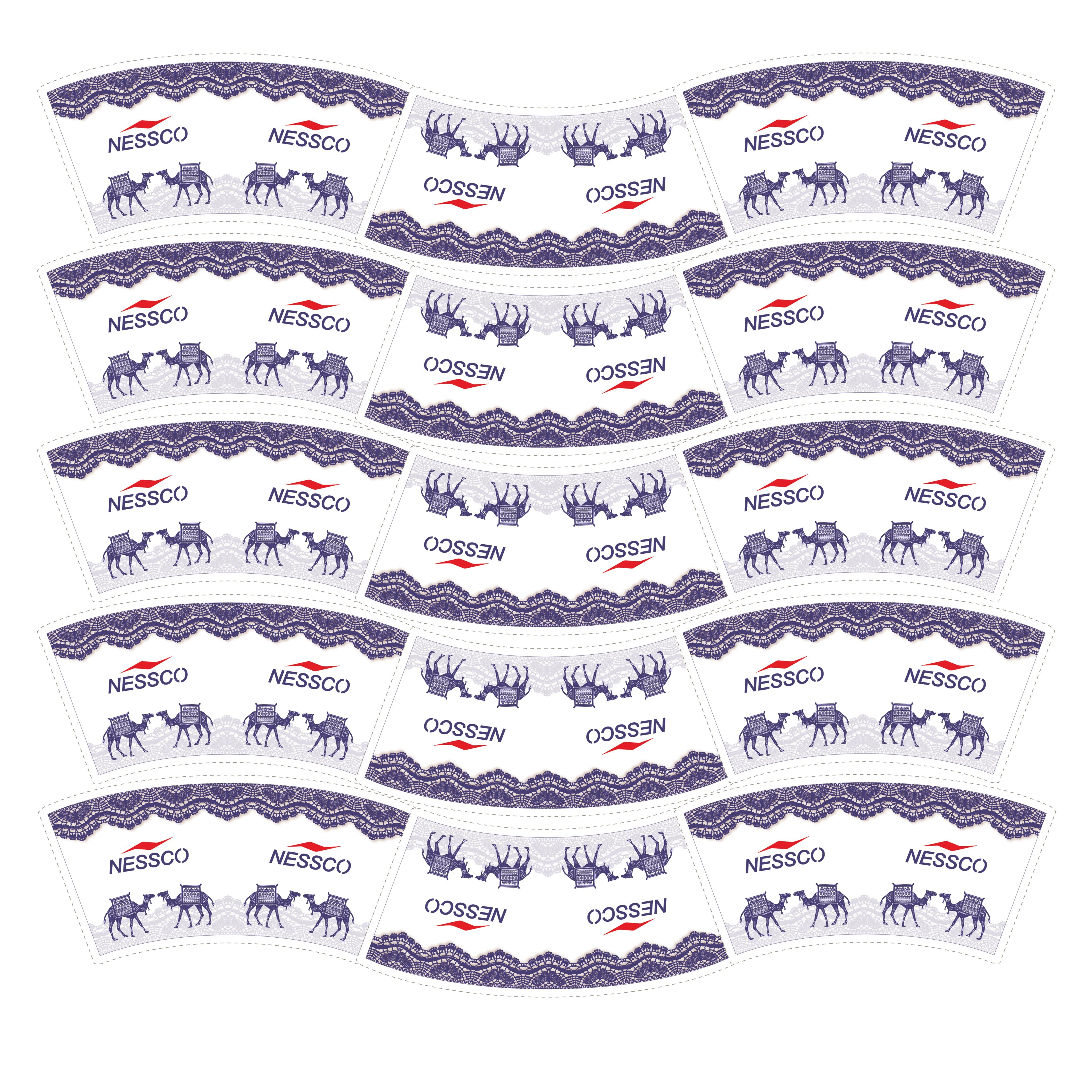

2. Printing

In the printing stage, the paper is fed into a high-speed printing machine that applies custom designs, logos, and other branding elements to the paper. This step is essential for creating branded cups that can be used for promotional purposes in cafes, restaurants, and events.

3. Cutting

After printing, the paper rolls are sent to the cutting machine, where they are precisely cut into flat, fan-shaped pieces known as blanks. These blanks will form the body of the paper cup. Accurate cutting is critical to ensure that the pieces fit together perfectly during the forming stage, avoiding any gaps or misalignment.

4. Paper Fan

The cut blanks are then shaped into a fan-like structure, ready to be formed into the cylindrical body of the cup. This step is important as it begins to give the paper its cup-like shape. The fan-shaped blanks are designed to make it easier to form a tight seam when the edges are joined together.

5. Forming

In this stage, the paper fan is rolled into a cylindrical shape, and the edges are sealed together to form the body of the cup. The machine uses heat and pressure to bond the edges of the paper and create a strong seam. This step transforms the flat blanks into the final cup shape, which is then ready for the next stage.

6. Final Product

Once the cup body is formed, the bottom of the cup is sealed using a separate machine. This step involves applying a bottom piece and sealing it with heat and pressure to ensure the cup is watertight. This final step ensures that the cup can hold liquids without leaking.

Applications

Technical Specifications

| FEATURE | SPECIFICATION |

|---|---|

| Speed | 100 Pcs/Min. |

| Paper Specifications | 170-380 GSM |

| Raw Materials | Single/Double PE/PLA Coated Paper |

| Size | 16Oz/480Ml-24oz/720Ml |

| Top Dia (TD) | 120mm (Max.) |

| Height (H) | 180mm (Max.) |

| Bottom Dia (RB) | 93mm (Max.) |

| Voltage | 380V,50Hz |

| Weight | 3550 Kg |

| Air Pressure | 6-8 Bar |

Want to Know More? Enquire Now

Download Brochure

Nessco Paper Cup Machine Catalogue

Want to Know More? Enquire Now

Download Brochure

Nessco Paper Cup Machine Catalogue

.webp&w=3840&q=75)

.webp&w=3840&q=75)

.webp&w=3840&q=75)